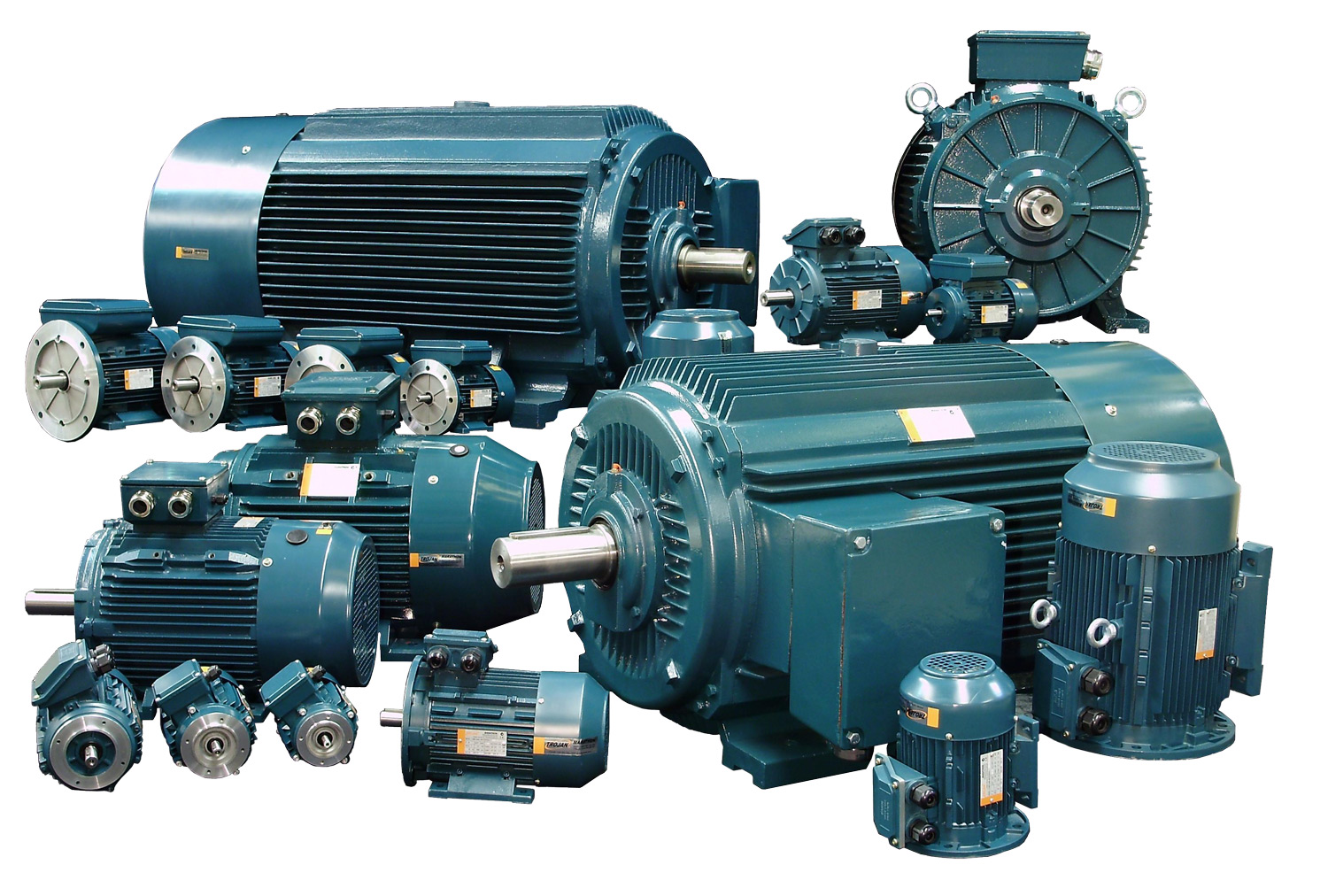

Product Description

Product application:

Y2 series HV motors are CHINAMFG motors, they are used to drive Blowers, Compressor, Pumps, Crusher, Stock-removings and other general-purpose machinery. They can serve as the prime movers in power plants, steel, coal mines, mechanical industries etc field.

Product attribute:

Frame size: H355~560mm

Power range: 185kW~2400kW

Poles: 2~8

Rated voltage: 3000~3300V

Frequency: 50Hz\60Hz

Insulation class: F,H

Degree of protection: IP44. IP54. IP55

Mounting arrangemnt: IMB3

Cooling method: IC411

Type duty: S1

The motor has such advantage as high efficiency, energy-saving, low noise, low vibration, light weight and reliable performance. They are easy for installation and maintenance.

| Induction Electric Motors Type Y/Y2/Y3/YX3/YE2 | ||||||||||||||

| Height of an axis, mm | Power, kW at frequency of rotation | The size of a shaft, mm at frequency of rotation | The connecting sizes, mm | |||||||||||

| 2р=2 | 2р=4 | 2р=6 | 2р=8 | 2p=2 | others | |||||||||

| H | 3000 | 1500 | 1000 | 750 | DxE | B | C | A | K | M | nxS | P | N | |

| min -1 | min -1 | min -1 | min -1 | |||||||||||

| 80M1 | 0.75 | 0.55 | 0.37 | 0.18 | 19×40 | 100 | 50 | 125 | 10 | 165 | 4×12 | 200 | 130 | |

| 80M2 | 1.1 | 0.75 | 0.55 | 0.25 | ||||||||||

| 90S | 1.5 | 1.1 | 0.75 | 0.37 | 24×50 | 100 | 56 | 140 | 10 | 165 | 4×12 | 200 | 130 | |

| 90L | 2.2 | 1.5 | 1.1 | 0.55 | 125 | |||||||||

| 100L | 3 | 2.2/3 | 1.5 | 0.75/1.1 | 28×60 | 140 | 63 | 160 | 12 | 215 | 4×14.5 | 250 | 180 | |

| 112М | 4 | 4 | 2.2 | 1.5 | 28×60 | 140 | 70 | 190 | 12 | 215 | 4×14.5 | 250 | 180 | |

| 132S | 5.5/7.5 | 5.5 | 3 | 2.2 | 38×80 | 140 | 89 | 216 | 12 | 265 | 4×14.5 | 300 | 230 | |

| 132М | x | 7.5 | 4/5.5 | 3 | 178 | |||||||||

| 160M | 11/15 | 11 | 7.5 | 4/5.5 | 42×110 | 210 | 108 | 254 | 14.5 | 300 | 4×18.5 | 350 | 250 | |

| 160L | 18.5 | 15 | 11 | 7.5 | 254 | |||||||||

| 180M | 22 | 18.5 | х | х | 48×110 | 241 | 121 | 279 | 14.5 | 300 | 4×18.5 | 350 | 250 | |

| 180L | х | 22 | 15 | 11 | 279 | |||||||||

| 200L | 30/37 | 30 | 18.5/22 | 15 | 55×110 | 305 | 133 | 318 | 18.5 | 350 | 4×18.5 | 400 | 300 | |

| 225S | х | 37 | x | 18.5 | 55×110 | 60×140 | 286 | 149 | 356 | 18.5 | 400 | 8×18.5 | 450 | 350 |

| 225М | 45 | 45 | 30 | 22 | 311 | |||||||||

| 250М | 55 | 55 | 37 | 30 | 60×140 | 65×140 | 349 | 168 | 406 | 24 | 500 | 8×18.5 | 550 | 450 |

| 280S | 75 | 75 | 45 | 37 | 65×140 | 75×140 | 368 | 190 | 457 | 24 | 500 | 8×18.5 | 550 | 450 |

| 280М | 90 | 90 | 55 | 45 | 419 | |||||||||

| 315S | 110 | 110 | 75 | 55 | 65×140 | 80×170 | 406 | 216 | 508 | 28 | 600 | 8×24 | 660 | 550 |

| 315М | 132 | 132 | 90 | 75 | 457 | |||||||||

| 315L | 160/185/200 | 160/185/200 | 110/132 | 90/110 | 508 | |||||||||

| 355M | 220/250 | 220/250 | 160/185/200 | 132/160 | 75×140 | 95×170 | 560 | 254 | 610 | 28 | 740 | 8×24 | 800 | 680 |

| 355L | 280/315 | 280/315 | 220/250/280 | 200 | 630 | |||||||||

| 355 | 355/375 | 355/375 | 315/355 | 220/250 | 80×170 | 110×210 | 800 | 224 | 630 | 35 | 840 | 8×24 | 900 | 780 |

| Application: | Industrial |

|---|---|

| Speed: | Constant Speed |

| Number of Stator: | Three-Phase |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you provide examples of machinery or equipment that rely on electric motors?

Electric motors are extensively used in various machinery and equipment across different industries. They play a crucial role in converting electrical energy into mechanical energy to power a wide range of applications. Here are some examples of machinery and equipment that heavily rely on electric motors:

- Industrial Machinery: Electric motors are found in numerous industrial machinery and equipment, such as pumps, compressors, fans, conveyors, agitators, mixers, and machine tools. These motors provide the necessary power for moving fluids, gases, and materials, as well as driving mechanical processes in manufacturing, mining, construction, and other industrial applications.

- Electric Vehicles: Electric motors are the primary propulsion system in electric vehicles (EVs) and hybrid electric vehicles (HEVs). They provide the power needed to drive the wheels and propel the vehicle. Electric motors in EVs and HEVs offer high efficiency, instant torque, and regenerative braking capabilities, contributing to the advancement of sustainable transportation.

- Household Appliances: Many household appliances rely on electric motors for their operation. Examples include refrigerators, air conditioners, washing machines, dishwashers, vacuum cleaners, blenders, and electric fans. Electric motors enable the movement, cooling, or mechanical functions in these appliances, enhancing convenience and efficiency in daily household tasks.

- HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems utilize electric motors for various functions. Motors power the fans in air handling units, circulate air through ducts, and drive compressors in air conditioning and refrigeration systems. Electric motors in HVAC systems contribute to efficient temperature control and air circulation in residential, commercial, and industrial buildings.

- Medical Equipment: Electric motors are essential components in a wide array of medical equipment. Examples include MRI machines, X-ray machines, CT scanners, surgical robots, dental drills, infusion pumps, and patient lifts. These motors enable precise movements, imaging capabilities, and mechanical functions in medical devices, supporting diagnostics, treatment, and patient care.

- Power Tools: Electric motors are commonly used in power tools such as drills, saws, grinders, sanders, and routers. They provide the rotational force and power required for cutting, shaping, drilling, and other tasks. Electric motors in power tools offer portability, ease of use, and consistent performance for both professional and DIY applications.

- Aircraft Systems: Electric motors are increasingly utilized in aircraft systems. They power various components, including landing gear actuation systems, fuel pumps, hydraulic systems, and cabin air circulation systems. Electric motors in aircraft contribute to weight reduction, energy efficiency, and improved reliability compared to traditional hydraulic or pneumatic systems.

These examples represent just a fraction of the machinery and equipment that rely on electric motors. From industrial applications to household appliances and transportation systems, electric motors are integral to modern technology, providing efficient and reliable mechanical power for a wide range of purposes.

Can electric motors be used in renewable energy systems like wind turbines?

Yes, electric motors can be used in renewable energy systems like wind turbines. In fact, electric motors play a crucial role in converting the kinetic energy of the wind into electrical energy in wind turbines. Here’s a detailed explanation of how electric motors are utilized in wind turbines and their role in renewable energy systems:

Wind turbines are designed to capture the energy from the wind and convert it into electrical power. Electric motors are used in wind turbines to drive the rotation of the turbine blades and generate electricity through the following process:

- Wind Capture: The wind turbine blades are designed to efficiently capture the kinetic energy of the wind. As the wind blows, it causes the blades to rotate.

- Blade Rotation: The rotational motion of the turbine blades is achieved through electric motors known as pitch motors. Pitch motors adjust the angle or pitch of the blades to optimize their orientation relative to the wind direction. The electric motors drive the mechanical mechanism that rotates the blades, allowing them to capture the maximum energy from the wind.

- Power Generation: The rotation of the wind turbine blades drives the main shaft of the turbine, which is connected to an electric generator. The generator consists of another electric motor known as the generator motor or generator rotor. The rotational motion of the generator rotor within a magnetic field induces an electrical current in the generator’s stator windings, producing electricity.

- Power Conversion and Distribution: The electricity generated by the wind turbine’s generator motor is typically in the form of alternating current (AC). To make it compatible with the electrical grid or local power system, the AC power is converted to the appropriate voltage and frequency using power electronics such as inverters. These power electronics may also incorporate electric motors for various conversion and control functions.

- Integration with Renewable Energy Systems: Wind turbines, equipped with electric motors, are integrated into renewable energy systems to contribute to the generation of clean and sustainable power. Multiple wind turbines can be connected together to form wind farms, which collectively generate significant amounts of electricity. The electricity produced by wind turbines can be fed into the electrical grid, used to power local communities, or stored in energy storage systems for later use.

Electric motors in wind turbines enable the efficient conversion of wind energy into electrical energy, making wind power a viable and renewable energy source. The advancements in motor and generator technologies, along with control systems and power electronics, have enhanced the performance, reliability, and overall efficiency of wind turbines. Additionally, electric motors allow for precise control and adjustment of the turbine blades, optimizing the energy capture and minimizing the impact of varying wind conditions.

Overall, the use of electric motors in wind turbines is instrumental in harnessing the power of wind and contributing to the generation of clean and sustainable energy in renewable energy systems.

What is an electric motor and how does it function?

An electric motor is a device that converts electrical energy into mechanical energy. It is a common type of motor used in various applications, ranging from household appliances to industrial machinery. Electric motors operate based on the principle of electromagnetism and utilize the interaction between magnetic fields and electric current to generate rotational motion. Here’s a detailed explanation of how an electric motor functions:

- Basic Components: An electric motor consists of several key components. These include a stationary part called the stator, which typically contains one or more coils of wire wrapped around a core, and a rotating part called the rotor, which is connected to an output shaft. The stator and the rotor are often made of magnetic materials.

- Electromagnetic Fields: The stator is supplied with an electric current, which creates a magnetic field around the coils. This magnetic field is typically generated by the flow of direct current (DC) or alternating current (AC) through the coils. The rotor, on the other hand, may have permanent magnets or electromagnets that produce their own magnetic fields.

- Magnetic Interactions: When an electric current flows through the coils in the stator, it generates a magnetic field. The interaction between the magnetic fields of the stator and the rotor causes a rotational force or torque to be exerted on the rotor. The direction of the current and the arrangement of the magnetic fields determine the direction of the rotational motion.

- Electromagnetic Induction: In some types of electric motors, such as induction motors, electromagnetic induction plays a significant role. When alternating current is supplied to the stator, it creates a changing magnetic field that induces voltage in the rotor. This induced voltage generates a current in the rotor, which in turn produces a magnetic field that interacts with the stator’s magnetic field, resulting in rotation.

- Commutation: In motors that use direct current (DC), such as brushed DC motors, an additional component called a commutator is employed. The commutator helps to reverse the direction of the current in the rotor’s electromagnets as the rotor rotates. By periodically reversing the current, the commutator ensures that the magnetic fields of the rotor and the stator are always properly aligned, resulting in continuous rotation.

- Output Shaft: The rotational motion generated by the interaction of the magnetic fields is transferred to the output shaft of the motor. The output shaft is connected to the load, such as a fan blade or a conveyor belt, allowing the mechanical energy produced by the motor to be utilized for various applications.

In summary, an electric motor converts electrical energy into mechanical energy through the interaction of magnetic fields and electric current. By supplying an electric current to the stator, a magnetic field is created, which interacts with the magnetic field of the rotor, causing rotational motion. The type of motor and the arrangement of its components determine the specific operation and characteristics of the motor. Electric motors are widely used in numerous devices and systems, providing efficient and reliable mechanical power for a wide range of applications.

editor by CX 2023-10-20